Boost Performance With Aftermarket Components: an Overview for Heavy Machinery Owners

Advantages of Aftermarket Components

Proprietors of hefty equipment can appreciate countless advantages by choosing for aftermarket parts over original tools manufacturer (OEM) parts. Aftermarket components are typically extra inexpensive than OEM components, permitting machinery owners to reduce upkeep and repair service expenses without compromising on top quality.

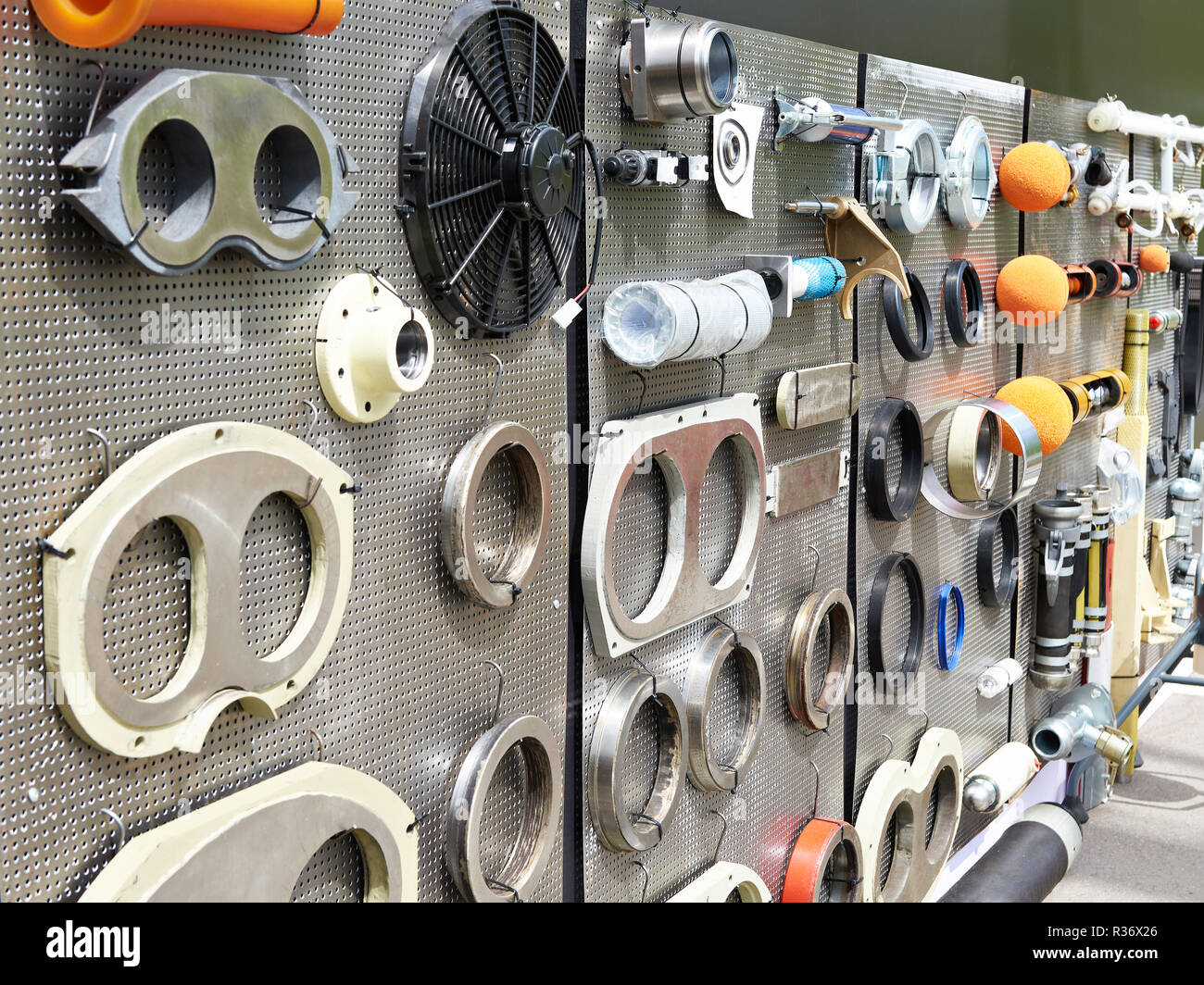

Given that aftermarket makers specialize in generating certain parts, equipment proprietors have access to a broader variety of options to suit their demands. Aftermarket parts are recognized for their top quality and reliability, with several conference or going beyond OEM criteria.

Lastly, selecting aftermarket components can also cause faster fixings and decreased downtime. With much easier availability and quick shipping choices, machinery owners can get their tools up and running once again promptly, reducing disruptions to their procedures.

Selecting the Right Aftermarket Components

When taking into consideration aftermarket parts for heavy equipment, it is necessary to focus on compatibility and quality to ensure ideal performance and long life of the devices. Selecting the appropriate aftermarket parts can be a vital choice for hefty equipment proprietors as it directly affects the efficiency and dependability of their devices.

Secondly, quality should never be compromised when picking aftermarket parts (aftermarket construction parts). Choosing premium parts ensures sturdiness, dependability, and general efficiency of the equipment. It is a good idea to resource aftermarket parts from credible suppliers or vendors known for their high quality requirements

Furthermore, thinking about elements such as service warranties, consumer reviews, and compatibility with existing systems can even more help in making the right option. By prioritizing compatibility and high quality when choosing aftermarket parts, hefty equipment owners can boost the efficiency and longevity of their equipment.

Installment and Upkeep Tips

For efficient procedure and longevity of hefty machinery, proper installment and regular upkeep are critical. When setting important site up aftermarket parts, make certain that you meticulously adhere to the maker's guidelines to guarantee optimal efficiency. By prioritizing setup and upkeep procedures, you can optimize the performance and life expectancy of your heavy machinery, inevitably conserving time and money in the long run.

Cost-Effectiveness of Aftermarket Parts

Correct installation and regular This Site maintenance are foundational aspects for heavy machinery owners intending to evaluate the cost-effectiveness of aftermarket parts for their equipment. While original equipment manufacturer (OEM) parts are known for their quality, aftermarket parts provide a more economical option without jeopardizing performance. By thoroughly examining the high quality and compatibility of aftermarket parts with their machinery, owners can strike a balance in between cost-effectiveness and efficiency, eventually making best use of the performance and long life of their heavy equipment.

Optimizing Performance With Aftermarket Upgrades

To improve operational performance and performance, hefty machinery owners can properly maximize performance via critical use of aftermarket upgrades. Aftermarket upgrades provide the opportunity to customize heavy equipment to certain operational demands, causing enhanced functionality and result. Upgrading components such as engines, transmissions, hydraulic systems, and tracks can dramatically improve the overall performance of the machinery.

Regularly examining the performance of heavy machinery and recognizing areas where aftermarket upgrades can be useful is vital for making the most of efficiency. By purchasing high quality aftermarket components and upgrades, machinery owners can accomplish greater degrees of effectiveness, inevitably leading to cost savings and enhanced functional end results.

Conclusion

To conclude, aftermarket components supply various benefits for hefty equipment proprietors, consisting of cost-effectiveness, increased efficiency, and personalization choices. By picking the ideal aftermarket components, complying with correct installment and maintenance treatments, and optimizing upgrades, hefty equipment proprietors can improve their equipment's efficiency and longevity. Purchasing aftermarket parts can eventually cause enhanced efficiency and lowered downtime, making it a rewarding consideration for owners wanting to optimize their machinery operations.

Proprietors of hefty machinery can take pleasure in many benefits by opting for aftermarket parts over initial tools maker (OEM) parts. Aftermarket parts are generally much more affordable than OEM components, enabling machinery owners to lower upkeep and repair service costs without compromising on top quality. By meticulously reviewing the high quality and compatibility of aftermarket parts with their equipment, proprietors can strike a balance in between cost-effectiveness and performance, ultimately maximizing the performance and durability of their heavy tools.

In final thought, aftermarket parts use many benefits for hefty machinery proprietors, including cost-effectiveness, boosted effectiveness, and customization alternatives. By choosing the appropriate aftermarket parts, following appropriate installation and upkeep procedures, and making best use of upgrades, heavy machinery proprietors can boost their devices's performance and durability.

Comments on “Make Certain Project Success: The Relevance of Aftermarket Construction Parts Procurement”